The fact that you've found yourself here suggests you have concrete to pour and a vague idea that concrete pump hire might save you time, effort and money.

It's certainly true that pumping concrete to where you need it offers several important advantages over conventional methods such as barrowing.

Here are a few of those advantages:

- Concrete pump hire is less labour-intensive than barrowing.

- It's more efficient, allowing you to move concrete quickly and over large distances.

- It's safer, because repeated trips with a wheelbarrow can put yourself or your team at risk.

- It's more precise, as the discharge hose can be placed wherever concrete is needed.

- It results in a higher quality finish as the continuous flow of concrete ensures a more uniform and consistent pour.

- It can be less expensive because it reduces labour costs and speeds up the pour, allowing mixing trucks to turnaround more quickly.

- It allows you to get concrete to areas that are otherwise inaccessible or difficult to access.

So it seems like the case has already been made in favour of concrete pump hire, but in fact there are scenarios where it may not be the correct solution, something we'll dig into later.

There's also plenty to think about prior to hiring a pump and some preparation to be done before the pump arrives on-site.

Understanding concrete pumping

Concrete pumps have been essential tools in commercial, industrial and large-scale residential construction contexts for many years, but are growing in popularity amongst DIYers and construction professionals working on smaller projects.

What is a concrete pump?

A concrete pump is a machine used to move "pump mix" concrete from either a volumetric mixer that can mix product on site, or a drum mixer that's been despatched from a nearby batching plant.

The concrete is pumped through pipes and hoses using hydraulic pistons, making it possible to supply the material directly to where it's needed, regardless of the scale of the project or the obstacles on site.

Concrete pumps are important in a modern construction industry context because they offer a solution to the limitations of more traditional methods, ensuring a steady and reliable flow of concrete, which is crucial for maintaining quality and meeting project timelines.

Types of concrete pump

Concrete pumps are divided into a few main types, with each able to serve different needs:

Boom pumps

Mounted on trucks, these powerful pumps have a robotic arm (or boom) that can extend to various lengths, allowing concrete to be delivered to great heights or distances and over tall obstacles.

Boom pumps are commonly used in large construction projects, such as high-rise buildings or where the site is spread out.

Ground line pumps

Smaller than boom pumps, line pumps can be truck or trailer-mounted and are ideal for projects that require concrete to be pumped quickly and precisely, but at a lower volume.

They are extremely versatile and can navigate through tighter spaces - for example, pipes can be run right through a property to a rear garden from the front road. This makes them ideally suited to residential or small commercial projects where access is tight but the pumping distance is not too significant (max. ~300m).

Line pumps also tend to be less expensive to hire than a boom pump, and smaller, which may be critical if you're working on a construction site that's difficult to access.

Static pumps and truck-mounted pumps

Static pumps are trailer-mounted so are fixed in one location once unhitched, but can also be mounted on light-duty trucks, allowing the efficient delivery of concrete on a platform that's able to move freely around your construction site.

Pumps can even be mounted on tracked vehicles, ideal for use on difficult terrain or in difficult weather conditions.

Choosing the right type of concrete pump depends on several factors, including project size, the distance the concrete needs to be pumped, and the complexity of the site.

By understanding the capabilities and limitations of each type of pump, construction professionals can make informed decisions that improve efficiency, reduce costs, and ensure the on-time completion of projects.

Concrete pump hire vs. barrowing

In both commercial and domestic construction contexts, the efficient delivery and accurate placement of concrete is critical to satisfying project timelines, reducing labour costs, and ensuring the overall quality of the finish.

Traditional methods such as barrowing and manual placement were long the staples for smaller projects, but with wider availability of concrete pump hire and a greater understanding of the benefits of pumping, even DIYers are looking to the pump to ensure greater efficiency and reduce the labour burden associated with moving concrete around site.

That said, there are scenarios where barrowing may still be appropriate. Our comparative analysis is intended to highlight the benefits of each approach.

Efficiency and speed

Concrete pump hire

The most significant benefit to hiring a concrete pump is the efficiency in time and labour that it can offer.

Concrete pumps are able to deliver concrete directly from the mixer to the pour site at a rapid rate. This method reduces the need for manual handling and speeds up the construction process, allowing for larger pours to be completed in a shorter timeframe.

Boom pumps and ground line pumps can extend over and around obstacles, delivering concrete across difficult terrain without the need for multiple handling steps.

Barrowing

Barrowing and manual placement are highly labour-intensive and time-consuming, especially over larger distances or when navigating obstacles on site.

However, these methods can prove viable for small-scale projects where the cost and logistics of hiring a pump may not be justified.

For example, barrowing may be the preferred approach if you're pouring shed, wall or garage footings that require relatively small amounts of concrete, delivered over short distances and on an accessible site.

Even so, make sure you have plenty of people on site to ensure a more or less continuous pour from the mixing truck to the pour site, as time is of the essence where pouring concrete is concerned. Aside from issues around the quality of the pour, ready mix suppliers often levy additional fees if their vehicles remain on site longer than expected.

Cost and labour considerations

Concrete pump hire

While the upfront cost of hiring a concrete pump may seem higher than relying on manual labour, the overall cost efficiencies that a pump offers can quickly become apparent even on smaller projects.

Unless it's a very small volume and straight-forward pour, the reduced labour requirements, faster completion times and decreased downtime can more than compensate for the initial expenditure.

Additionally, precise discharge hose placement can reduce waste, further enhancing cost-effectiveness. This is especially true if you're using a volumetric, "pay for what you lay" ready mixed concrete delivery service.

Barrowing

For small projects or where budget constraints are tight, manual methods can be cost-effective due to the minimal equipment required.

Projects like fence post or wall footings could just as well be accomplished using an electric drum mixer, where you mix the materials yourself on site.

However, the increased labour costs, potential for higher waste and slower completion rates can offset these initial savings as project size and complexity grow.

Quality of the pour

Concrete pump hire

One of the main benefits of concrete pump hire is that a concrete pump is able to deliver a continuous flow of concrete throughout the duration of the pour.

This can be particularly important for structural integrity and longevity, as the ability to place concrete directly where it's needed reduces the risk of segregation or weakening that can occur with multiple handling steps.

There are also aesthetic benefits to a continuous pour, as where concrete is exposed, any segregation will be evident and is likely to undermine the quality of the finish from a cosmetic point of view.

Barrowing

Manual methods may result in a less uniform placement due to the variability in mixing, moving and pouring the concrete.

The risk of quality issues increases with the volume of concrete and the complexity of the pour site, potentially affecting the structural quality of the finished structure.

This shouldn't be a concern for very small jobs such as shed footings, fence posts and the like, as the volume of concrete involved is low and therefore no segregation should occur if the pour is planned well and the ground prepared beforehand.

Accessibility and range of application

Concrete pump hire

One of the clearest advantages of concrete pumps is their ability to access hard-to-reach areas, whether that involves going over, under or through obstacles, or simply due to the distance from the mixing truck to the pour site.

This increased accessibility expands the range of projects that can be undertaken, from high-rise buildings to foundations laid in constrained spaces.

Barrowing

Manual placement is limited by your team's physical ability to transport the concrete.

Barrows can navigate small obstacles but are impractical for significant heights or distances, being better suited to sites with easy access and less complex logistical requirements.

Environmental considerations

Concrete pump hire

While most concrete pumps are diesel fuelled, by reducing the number of trips and amount of machinery required to transport concrete from the mixer to where it's needed, pumps can lower the carbon footprint of a construction project.

The precision in placement also minimises waste, contributing to more sustainable construction practices.

Barrowing

Repeated trips and the physical handling involved in manual methods can increase your project's environmental impact, especially if using a mini dumper.

Even the addition of extra people to help barrow can have an environmental impact as it will be necessary for them to travel to the site.

Additionally, the potential for increased waste can further detract from sustainability goals.

Safety

Concrete pump hire

Reducing the need for the manual handling and movement of concrete can significantly lower the risk of injuries on site.

Concrete pumps also keep the site less cluttered with equipment and materials, reducing trip hazards and improving overall site safety.

Barrowing

Traditional methods such as barrowing are accompanied by inherent risks, particularly from manual handling injuries and the potential for accidents in transporting materials across the site.

Barrowing in high-pressure situations where you need to get concrete to the pour site quickly can lead to injury - usually turned or broken ankles.

These risks are increased when there are more people on site, working in relay and sometimes pushing barrows in slippery conditions, over narrow boards, up and down slopes, and around various obstacles.

The intense labour required will also lead to fatigue among workers, potentially compromising safety standards, as tired workers tend to make more mistakes and pay less attention to risk.

Versatility

Concrete pump hire

The versatility of concrete pumps, with a multitude of different types and sizes available, means they can be used effectively in a range of construction contexts.

Boom pumps capable of reaching high elevations and line pumps suited for extending into narrow spaces allow for tailored solutions based on specific project needs, from large-scale civil engineering projects to domestic garage footings.

It may also be possible to use a large pump on a smaller project and vice versa, depending on how well the pour is planned and issues around access.

This adaptability ensures efficient concrete placement across a variety of scenarios, with the potential to significantly enhance productivity and reduce labour costs.

In essence, the versatility of concrete pump hire significantly broadens the scope of projects that can be undertaken, ensuring precise, efficient, and flexible concrete delivery.

Barrowing

While traditional methods of delivering concrete can be the correct approach on small-scale projects that involve low volumes of concrete, the effectiveness of such methods diminish as the complexity and scale of a project increases.

Barrowing or manual placement of product only remains practical for small, straightforward projects where the logistical setup for pump hire would not offer significant advantages.

The best way to get concrete where you need it

So while it's clear that we believe that the manual transportation or mixing of concrete on site in a compact drum mixer still has a place in the construction industry, particularly for smaller or less complex projects, the benefits of concrete pump hire are undeniable for medium to large-scale endeavours.

The efficiency, speed, and safety enhancements, coupled with reduced labour requirements and an improvement in quality all present a compelling case for the adoption of concrete pump technology in many construction scenarios.

While the initial cost of pump hire can seem daunting, it can be seen as an investment in the project's overall success, offering returns in the form of faster completion times, reduced waste, and superior structural integrity.

Planning for concrete pump hire

Before the concrete pump and ready mix truck arrive on site, it's essential that you plan the pour meticulously to ensure not only the efficiency of the operation but also the safety of everyone involved.

Even relatively small pours can go awry if the groundwork hasn't been completed properly.

The planning phase can be divided into three main components:

Site preparation and access considerations

The first step in planning for concrete pump hire involves preparing the site and ensuring adequate access for the pumping equipment.

A thorough site inspection should be conducted to identify potential obstacles, such as overhead power lines, uneven ground, or restricted access areas that could impede the pump's placement and operation.

It's essential to ensure that the ground where the pump will be stationed is level and stable enough to support the weight of the pump, especially for larger boom pumps, which require a solid foundation to operate safely.

Access routes for the concrete mixer trucks feeding the pump need to be evaluated for width, height, and load-bearing capacity to prevent disruptions in the supply of concrete. In urban or congested areas, coordinating with local authorities may be necessary to obtain permission for road closures or to temporarily use public spaces.

Likely weather conditions on site should also be considered, as soft ground may cause problems for the mixer trucks, truck-mounted concrete pump or the vehicle pulling a trailer-mounted pump. Lighter vehicles may fare better in these conditions, or if it's very difficult terrain then a pump mounted to a tracked vehicle would be preferable.

Before you pour: our preparation checklist

- Ensure access routes for concrete mixing trucks and the concrete pump are clear and stable

- Confirm the pump setup area is level, secure, and capable of supporting the equipment's weight

- Mark out the pour area clearly, including any hazards or no-go zones

- Check that all required permissions and notices for the work are in place

- Inspect formwork and reinforcement to ensure they are ready and secure

- Set up safety barriers and signage around the pouring area

- Arrange for sufficient lighting if work will continue during low light conditions

- Verify communications equipment is working and allows seamless coordination between teams

- Prepare contingency plans for changes in weather conditions or unexpected delays

- Conduct a final safety briefing for all personnel involved in the pour

Selecting the right pump for your project

Choosing the correct type of concrete pump is crucial for the success of your project.

The selection between boom pumps, known for their versatility and reach, and ground line pumps, suitable for smaller or more confined spaces, should be based on the specific requirements of your project.

Factors such as the volume of concrete needed, the distance from the mixer to the pour site, and the complexity of the site layout each play significant roles in this decision.

Consultation with the pump hire company can offer valuable insights into the most suitable pump type and size for your project. They can assess the project specifications and recommend a pump that not only meets your current needs but also offers flexibility for unforeseen requirements.

Safety measures and risk assessments

Implementing safety measures and conducting risk assessments are important aspects of the planning process of any concrete pour, irrespective of the scale of the project.

Safety begins with choosing a reputable pump hire company that adheres to the highest safety standards and provides experienced operators for their equipment.

Prior to the commencement of pumping operations, a comprehensive risk assessment should be carried out to identify potential hazards related to the pump operation and the construction site more generally.

This assessment must consider the risk of contact with electrical lines, the potential for trips and falls, and the possibility of concrete spillage or hose whip.

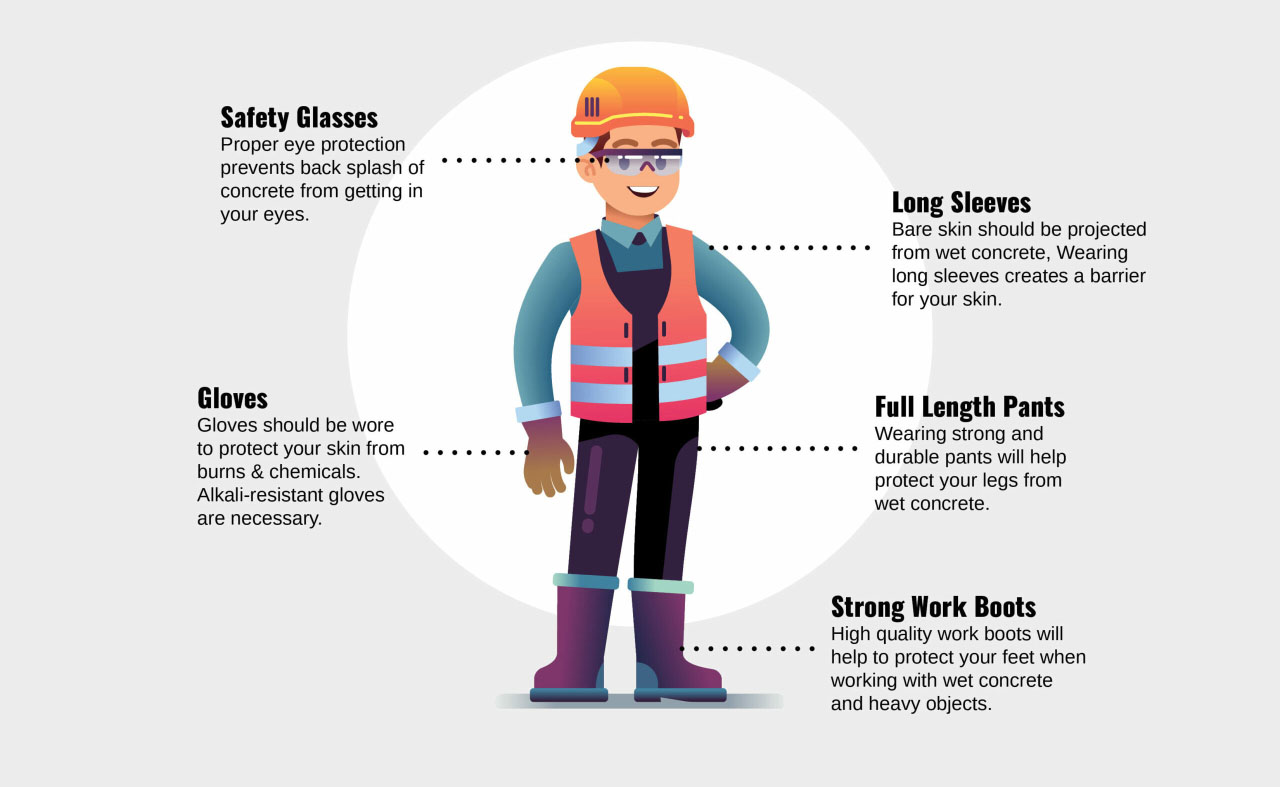

Safety measures should include the establishment of exclusion zones around the pumping area to protect personnel from hose whip injuries, the use of personal protective equipment (PPE) such as hard hats, safety glasses, and high-visibility vests, and the clear marking of all hazards on site.

Regular safety briefings and training sessions for all personnel involved in the pumping operation will further enhance safety awareness and preparedness.

In summary, the success of a concrete pour hinges on thorough planning, site preparation, pump selection, and the implementation of robust safety protocols. By taking care to consider each of these aspects of the operation, project managers can ensure the smooth execution of the pour itself and therefore the quality of the resulting structure.

Selecting a concrete pump hire service

Selecting the right concrete pump hire service is a crucial decision that can significantly impact the success of any construction project that involves a concrete pour.

The choice of provider should be made based on a comprehensive evaluation of several key criteria, including the reliability of the service, the quality of the equipment provided and the level of support offered.

Additionally, a thorough understanding of the contract terms and conditions, as well as the experience and expertise of the operators, are vital considerations that can affect both the efficiency of the project and the safety of the construction site.

Criteria for choosing a provider

Reputation

When assessing potential concrete pump hire services, the reliability of the provider should be a primary consideration.

A reliable service is characterised by a track record of punctuality, the ability to meet project deadlines and positive feedback from previous clients.

Feedback may come in the form of recommendations from acquaintances in the construction industry or online reviews from trusted sources, such as Google or Trustpilot.

Quality of equipment

Equally important is the quality of the equipment provided.

Modern, well-maintained pumps ensure not only the smooth execution of the pour but also minimise the risk of mechanical failures that could delay the project.

A mechanical failure in the middle of a pour will likely result in segmentation, leading to structural issues that could be costly and time consuming to rectify.

Level of service offered

The level of service provided is another important factor and includes the responsiveness of the company to enquiries, as well as their flexibility in accommodating changes to the specification or scope of the project.

The availability of additional services, such as site visits and consultations, can also be important as a complex pour is dependent on the most appropriate pumping solution being provided

Understanding contract terms and conditions

Before making a commitment to hire a concrete pump it's essential that you thoroughly review and understand the terms and conditions of the contract.

This review should cover the duration of the hire, the costs involved (including any additional charges for overtime or ancillary services), and the responsibilities of both parties in terms of equipment maintenance and insurance.

Clarity on these terms can help avoid unexpected expenses and disputes during the course of the project.

It is advisable to seek clarification on any points that are unclear and, if necessary, negotiate terms that better suit the requirements of your project.

A transparent and mutually agreeable contract is the foundation of a successful partnership between the construction project manager and the hire service provider.

Importance of operator experience and support services

The expertise of the operators provided with the concrete pump is a significant aspect of the hire service.

Experienced operators not only ensure the efficient and safe operation of the pumping equipment but also contribute valuable insights and suggestions for optimising the concrete pour. Their knowledge can be particularly beneficial in navigating the challenges of complex or unusual project sites.

If you have a complex pour you can't take any chances with your contractor. Ask for the details of similar projects they've completed and make sure they have contingencies in place if equipment fails on the job. No cutting corners with slump tests either. Make sure every batch is tested.

Concrete Constructions Ltd

Support services are an extension of this expertise. They include technical support, emergency response capabilities, and the provision of comprehensive training for construction staff involved in the pumping process. These services enhance the overall efficiency of the project and safeguard against potential issues that could arise during the operation of the pump.

Operational best practices

Achieving a successful pour when hiring a concrete pump requires adherence to a handful of operational best practices.

These practices are designed to ensure the efficient use of concrete pumps on-site, seamless coordination with the concrete supplier, and the ability to quickly address common issues through effective troubleshooting.

Implementing these strategies can significantly enhance the productivity and safety of construction projects.

Efficient use of concrete pumps on-site

Maximising the efficiency of concrete pumps starts with meticulous planning. Before the arrival of the pump and the concrete, a clear plan should be in place detailing the exact pouring locations and the sequence of pours.

This plan should consider the pump's reach and the layout of the site to avoid unnecessary repositioning of the pump, which can be time-consuming and costly, perhaps even impossible on some sites.

As mentioned earlier, preparation of the site is equally important.

Ensure that the area where the pump will be stationed is level and stable, with sufficient space for the pump and the delivery mixer trucks.

Clear signage and communication protocols should be established to guide the trucks to their correct positions, minimising delays in the unloading process.

Coordination with concrete supplier

The synchronisation between the concrete pump operation and the supply of concrete is critical to avoid delays and ensure a consistent pour.

This coordination begins with scheduling deliveries in accordance with the project's timeline, allowing for a steady supply of concrete without causing unnecessary waiting times for either the pump or the mixer trucks.

Communicating specific requirements for the concrete mix to the supplier is crucial, as different pours may require different mix designs or additives. The pump operator should be informed of any special characteristics of the mix, as this might affect the pumping process.

An ideal solution would be to use volumetric mixers that can mix the appropriate volume of product on-site, and a company that can also supply a pump, which should ensure better communication and increase the likelihood of a good pour.

Dealing with a single company also reduces the administrative burden, may be less expensive and can prevent a scenario where if issues arise, one party blames the other.

Common issues and troubleshooting tips

Despite careful planning, issues can arise during the operation of concrete pumps. Recognising and addressing these problems swiftly is key to minimising disruption to the project.

One common issue is blockages in the pipeline. This can be caused by the concrete starting to set within the pump or hose, often due to delays or interruptions in the pour.

To troubleshoot, first, try to reverse the pump to dislodge the blockage, then resume pumping slowly. If this does not clear the blockage, the line may need to be disconnected and manually cleared.

Another issue can be air getting trapped in the line, leading to inconsistent flow or surges of concrete. This is typically resolved by ensuring that the hopper remains sufficiently full during operation to prevent air from being drawn into the system.

Leaks in the pipeline or connections can also occur, usually due to wear or improper assembly. Regular inspection and maintenance of the equipment can prevent many such leaks, while on-the-spot repairs or replacement of worn parts may be necessary. The simple tightening of connections, or disconnection and reconnection, is often all that's needed.

In conclusion, the successful operation of concrete pumps hinges on effective planning, coordination with suppliers, and the ability to address common issues promptly.

By adhering to these operational best practices you can achieve efficient and safe concrete pumping, resulting in high-quality pours that can also help ensure your project comes in on time.

Frequently asked questions

How much space is required to set up a concrete pump?

There's no simple answer to this question as concrete pumps vary in size, and the space required to accommodate a vehicle-mounted pump depends on the footprint of the vehicle itself.

Typically, you're looking at something like 6x3m for a trailer-mounted pump, all the way up to 8x9m for a large truck-mounted boom pump with its outriggers deployed.

The largest boom pumps could also require an unobstructed radius of up to 100 metres in order to be safely operated, hence a ground line pump is the preferred option on small sites where space is at a premium.

I can't get a barrow down the side of my property - is there any way to deliver concrete to the back?

This is where a ground line pump is the ideal option. As long as a person can fit through the gap it should be possible to lay pipes to transport concrete to the rear of the property.

Concrete pump hire companies will carry a selection of bends and flexible pipes to allow them to meet each customers' specific requirements, but if you need to build a long run you should communicate this in advance to ensure enough piping is brought to site.

How far can concrete be pumped?

Hydraulic concrete pumps tend to be able to pump concrete around 300m in horizontal distance.

If you're using a ground line pump, the pipes come in 3m sections so you'd need 100 pipes to get the concrete where you need it.

This is quite a long distance and would likely require the company to carry more pipes than usual, so make sure you discuss the nature of the job with the company in advance of them arriving on site.

What's the difference between a boom and a ground line pump?

A boom pump is a large, truck-mounted pump with a robotic arm (boom) that can be remotely controlled to deliver concrete precisely where it's needed, ideal for reaching high or distant locations.

A ground line pump, on the other hand, uses a series of pipes or hoses laid on the ground to transport concrete from the pump to the pour site. Line pumps are best suited to sites with access restrictions where the concrete needs to be moved over long distances horizontally or to areas that the boom pump's arm cannot reach due to obstacles or tight spaces.

What information does a hire company usually require from the customer?

- Construction site address

- Volume of concrete to be pumped

- Required time on site (allowing for time to set up prior to the concrete arrival)

- Your details (name, company name, telephone number and email address)

We advise that you source concrete from the same company supplying the pump, and in which case you'll need to discuss mix requirements with them prior to delivery.

If you have any doubts about what information to share with the company, you should discuss the nature of the job with their team so that they can specify the concrete mix design and equipment required to achieve a successful pour.

How much time is required for pumping concrete?

The flow rate of concrete pumps tends to max out around 160 m3 per hour but is variable and as such, the time required for the pour will depend on the nature of the job and speed that the pump operator pumps the product.

Is concrete pumping messy?

Pumping tends to make less mess than barrowing or manual placement, but any job involving concrete is likely to get messy.

We'd recommend having a water supply to the pump and an area you can use to wash out.

Boom pumps typically finish a job with 7-8 barrows worth of concrete that can't be pumped and will need to be washed out into a washout box constructed from plywood or similar material.

Can concrete be pumped in all weather conditions?

Almost, but bear in mind that certain mixes of concrete don't fare well in wet or very cold conditions, so if in doubt be sure to check with your concrete supplier on the morning of the pour to ensure that the weather conditions are appropriate to proceed.

Boom pumps can also be susceptible to high wind due to the height of the boom. Safety considerations on-site could put a stop to the pour if winds are above a certain level, which will be determined by the pump operator.

Can any concrete be pumped?

Any spec of concrete considered to be "pump mix" can be pumped.

Pump mix is a concrete mix specification that contains additional sand and cement, allowing it to flow freely through hoses and pipelines.

How wet can the concrete be?

We advise that you discuss the specification of the mix you require with your supplier, who should know how much water can be added before the concrete is weakened or segregates.

Can screed be pumped?

Yes, wet screed can be pumped by most concrete pumps.

Dry screed will likely require a specialist screed pump due to the mixture having low moisture content and a lack of fluidity that could result in blockages during the pouring process.

Is a minimum volume required to pump concrete?

In practical terms, no, but many concrete suppliers and hire companies will struggle to turn a profit on low-volume jobs where only a cube or two of product needs to be pumped, and as such may not be interested in getting involved in the project.

Will a concrete pump hire company pump anyone's concrete?

Some will, others prefer not to, usually because there's a chance the concrete supplier delivers concrete that's not been mixed according to the specification that the pump hire company recommends.

This article is the oldest and is 5120 words long. Posted by Adam